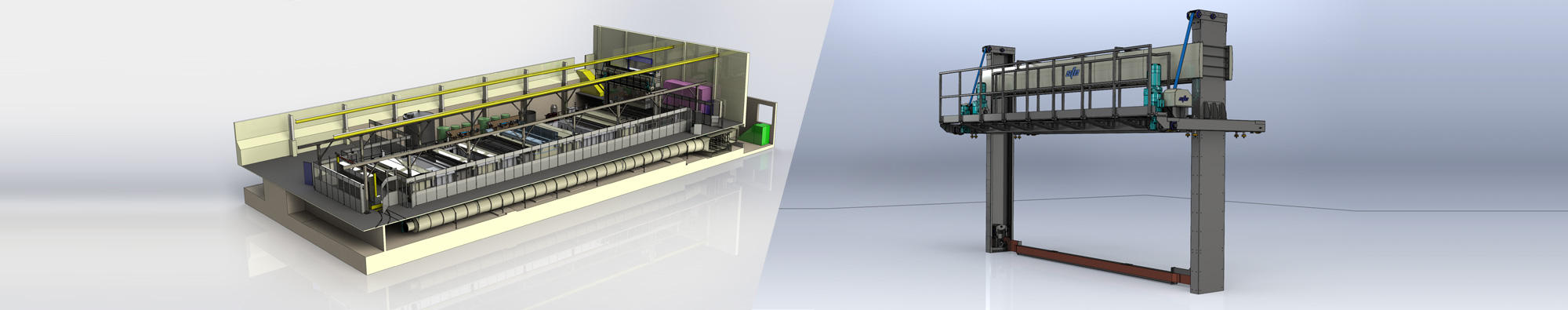

Surface Finishing Engineering Ltd (SFE) supply a wide range of automatic process plant systems. Our engineers have experience of automatic process lines from 0.5m wide for Formula 1 parts up to 18m wide for aircraft wing components.

As well as standard anodising, electro-plating, phosphate cleaning and etching, we also provide automatic FPI (Fluorescent Penetrant Inspection) equipment.

We focus on plant and equipment being engineered for the 21st Century; equipment is robust and importantly, careful attention is given to the aesthetics of the plant.

Features implemented to Improve aesthetic appearance include:

- Cladding around or attached to the equipment

- Neatness of equipment layout

- Materials being resistant to the chemicals and easy to clean

- Quality and appearance of the fabrications and overall construction of the plant

Equipment Basics

- Designed for minimal maintenance

- Equipment is easy to keep clean

- Transporter motors are high quality, requiring minimal inspections

- Lifting is via plastic webbing belts - no need to lubricate and no corrosion

- Transporter designed to ensure maintenance is accessible and safe to carry out

- Equal priority given to access for maintenance as well as operator access

Automation of the Process Line Systems

- Controlled via a PLC and computer HMI

- Software systems are purposely designed for the surface finishing industry

- Numerous features including traceability up to NADCAP standard and allows users to input and interrogate information to any level required

- System can be interfaced with the clients’ network allowing remote interrogation and can be connected for text and SMS messaging

- Inputting new process sequences are simple menu systems

- Parts are stored in a library which include a photograph of the part of how it should be mounted on to jigs

- Barcode entry is also a common feature to eliminate human error

- CCTV monitoring offered to reduce the need for personnel to carry out physical inspection

The Future of Automatic Process Lines

- Automatic transporter process lines have been around for 50 years however SFE have been moving things further with automation of processes only previously carried out manually

- Sophisticated analysis equipment and automatic dosing maintain chemistry in equilibrium

- Ensures consistency of processing and process specification compliance

- Part rotation can be implemented

- Automatic making and breaking electrical contacts and siphoning of liquids

- Automated emptying and filling systems, eliminating the need for transporting hazardous chemicals around site and stopping the dangerous practice of manually adding chemicals into the tanks

Good Engineering

- Good engineering is a top priority for SFE

- Simplicity of design and eliminating unnecessary complication whilst at the same time considering equipment longevity has led to numerous improvements

- Continuing value analysis in the design allows for significant improvements whilst at the same time reduces maintenance and risk of failures

leading to a reduction in costs thus increasing value to our customers.